The Simple Homes Blog

February 18, 2022

Understanding the Prefab Landscape

There are many different types and forms of prefab homes. Historically a relatively small part of the US construction market, interest in prefabricated homes is increasing. A recent Home Innovation Research Labs study showed increasing builder use of prefabrication and many consumers are looking to prefab as a solution to long construction timelines and ever-increasing costs. However as interest in prefab has increased, so has the confusion about the various types of prefab homes.

A continuum of prefabrication: Prefab runs a wide spectrum, from precut kit homes all the way to volumetric modular.

Precut lumber packages: In a trend that harkens back to the Sears Roebuck Kit Homes of the early 20th century, many builders and framers are starting to use precut framing packages to reduce on-site labor requirements and improve quality. Homes built using precut lumber packages are delivered to the site as loose lumber packs, with all material pre-cut in a factory. Studs, plates, and headers are bundled by wall, with identifiers on each stick matching corresponding construction drawings.

Open wall panels: Open wall panels are available from many local lumber yards and component manufacturers. Wall panels are sections of wood-framed exterior and exterior walls that are manufactured in a factory. These panels are designed based on the information provided in the construction documents for the building.

Panelized Building Systems (how we build at Simple Homes): Panelized building systems, like our Simple Shell, provide a higher level of factory finish than typical open wall panel construction. At Simple Homes, our panelized building system includes a pre-installed weather barrier (Huber Zip), pre-taped seams, and pre-installed windows and exterior doors. We also pre-manufacture 3D floor cassettes and roof panels in our Denver factory.

Volumetric Modular: Volumetric modular construction involves assembling fully-enclosed boxes in an off-site factory and then joining these boxes together on-site to construct the finished structure. These prefabricated modules typically involve a high level of factory finish - everything from framing to drywall, to flooring, to cabinetry.

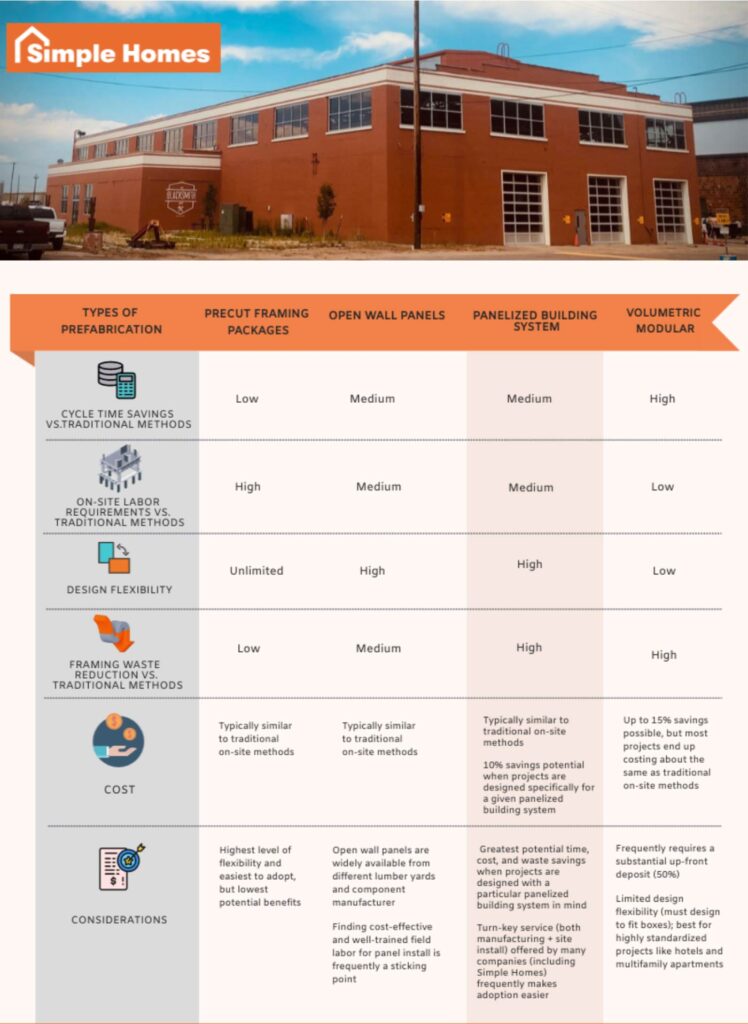

Advantages and disadvantages of different types of prefabrication Each type of prefab construction comes with its own advantages and disadvantages. What method is right for you will depend on your specific project. Check out the graphic below to learn more: